What is a stainless steel low-temperature ball valve Stainless steel low-temperature ball valve is a type of valve that undergoes cryogenic treatment by immersing in liquid nitrogen at -196 degrees Celsius. It adopts an extended rod low-temperature ball valve structure, in which the gland packing is above zero degrees Celsius to ensure that the packing can maintain normal self-lubricating sealing and stable performance. This type of valve is mainly used to output liquid low-temperature media, such as ethylene, liquid oxygen, liquid hydrogen, liquefied natural gas, liquefied petroleum products, etc. These media are not only flammable and explosive, but also need to vaporize when heated, and their volume expands hundreds of times during gasification. Stainless steel low-temperature ball valves are divided into two types: low-temperature floating ball valves and low-temperature fixed ball valves. For temperatures above -50 ℃, long neck structures are generally not used; For ball valves with temperatures below -50 ℃, the neck length is generally 250mm, or determined based on design and calculation. The main material of this valve is very important. If the material is not qualified, it may cause external or internal leakage of the shell and sealing surface. Therefore, the comprehensive mechanical properties, strength, and rigidity of the components must meet the requirements for use

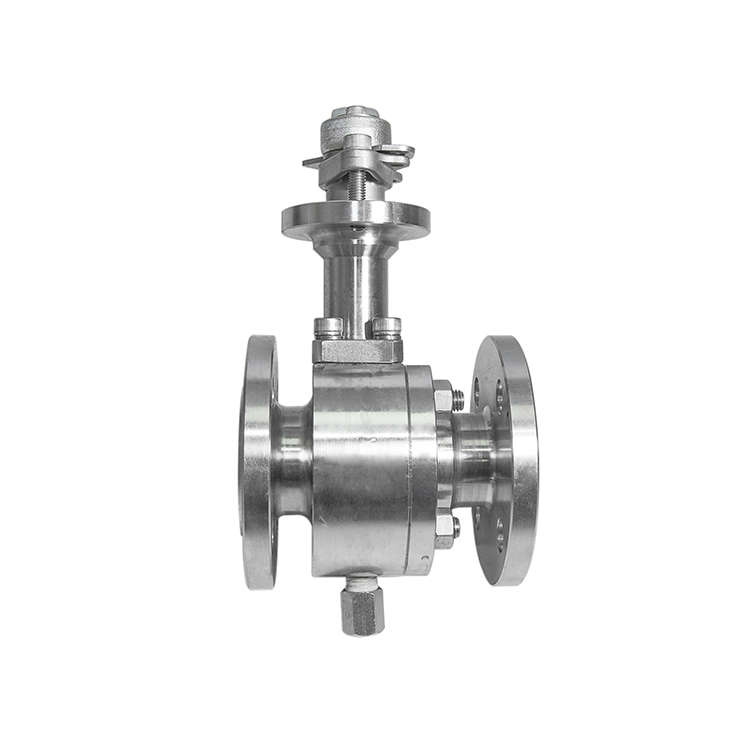

What is a stainless steel low-temperature ball valve?

Stainless steel low-temperature ball valve is a type of valve that undergoes cryogenic treatment by immersing in liquid nitrogen at -196 degrees Celsius. It adopts an extended rod low-temperature ball valve structure, in which the gland packing is above zero degrees Celsius to ensure that the packing can maintain normal self-lubricating sealing and stable performance. This type of valve is mainly used to output liquid low-temperature media, such as ethylene, liquid oxygen, liquid hydrogen, liquefied natural gas, liquefied petroleum products, etc. These media are not only flammable and explosive, but also need to vaporize when heated, and their volume expands hundreds of times during gasification. Stainless steel low-temperature ball valves are divided into two types: low-temperature floating ball valves and low-temperature fixed ball valves. For temperatures above -50 ℃, long neck structures are generally not used; For ball valves with temperatures below -50 ℃, the neck length is generally 250mm, or determined based on design and calculation. The main material of this valve is very important. If the material is not qualified, it may cause external or internal leakage of the shell and sealing surface. Therefore, the comprehensive mechanical properties, strength, and rigidity of the components must meet the requirements for use

Product Description:

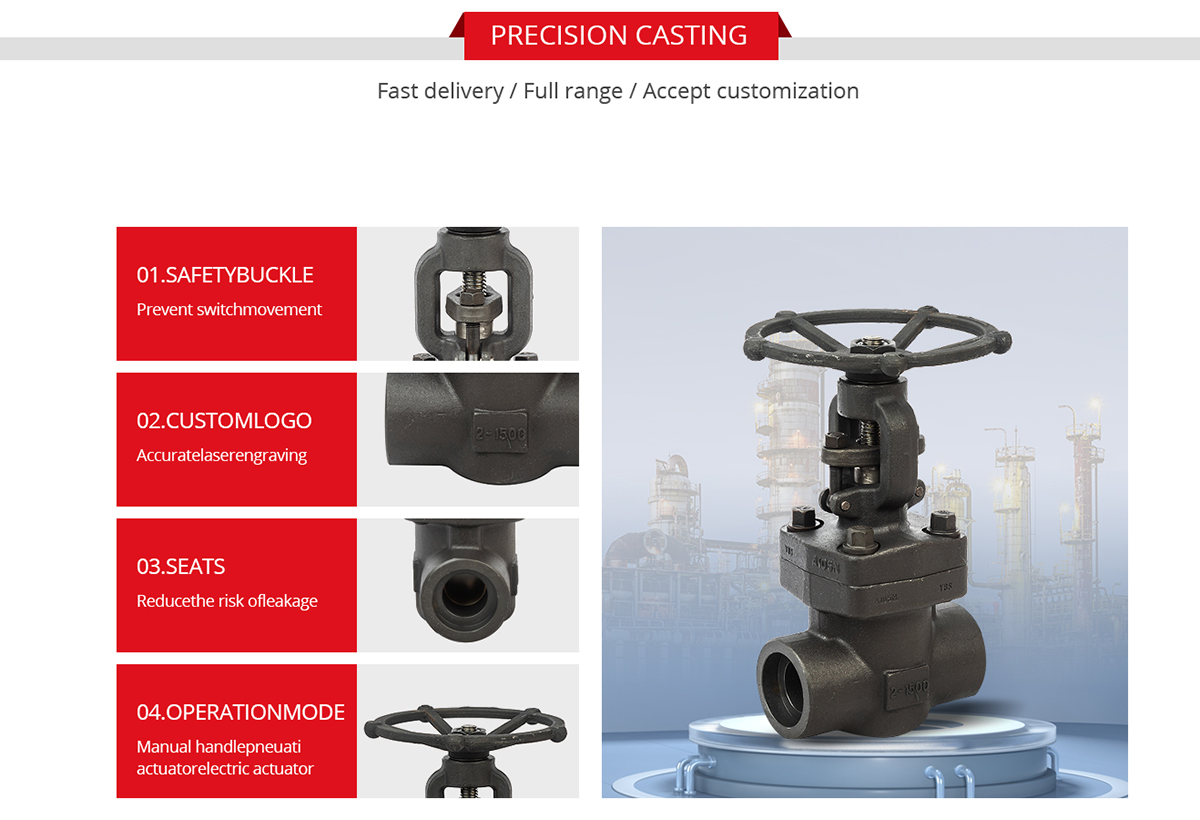

main features

Full diameter/reduced diameter

90 degree positioning and lockable structure

Special form of "Y" head handle

A pair of butterfly shaped spring pads facing each other

Anti blowing valve stem

Double sealing structure in the middle of the valve stem

Bolt and threaded gasket seal valve cover

Product specifications

Design Specification: API 6D

Structural length: ANSI B16.10

Connection standards: ANSI/ASME B1.20.1, ASME B16.11

Pressure test: API598/API6D

Product Range

Main material: forged steel

Nominal diameter: 3/8 "-2"

Pressure range: 150LB-2500LB

Applicable temperature: ≤ 120 ℃

Operation mode: manual, etc

Applicable media: water, steam, oil, etc.