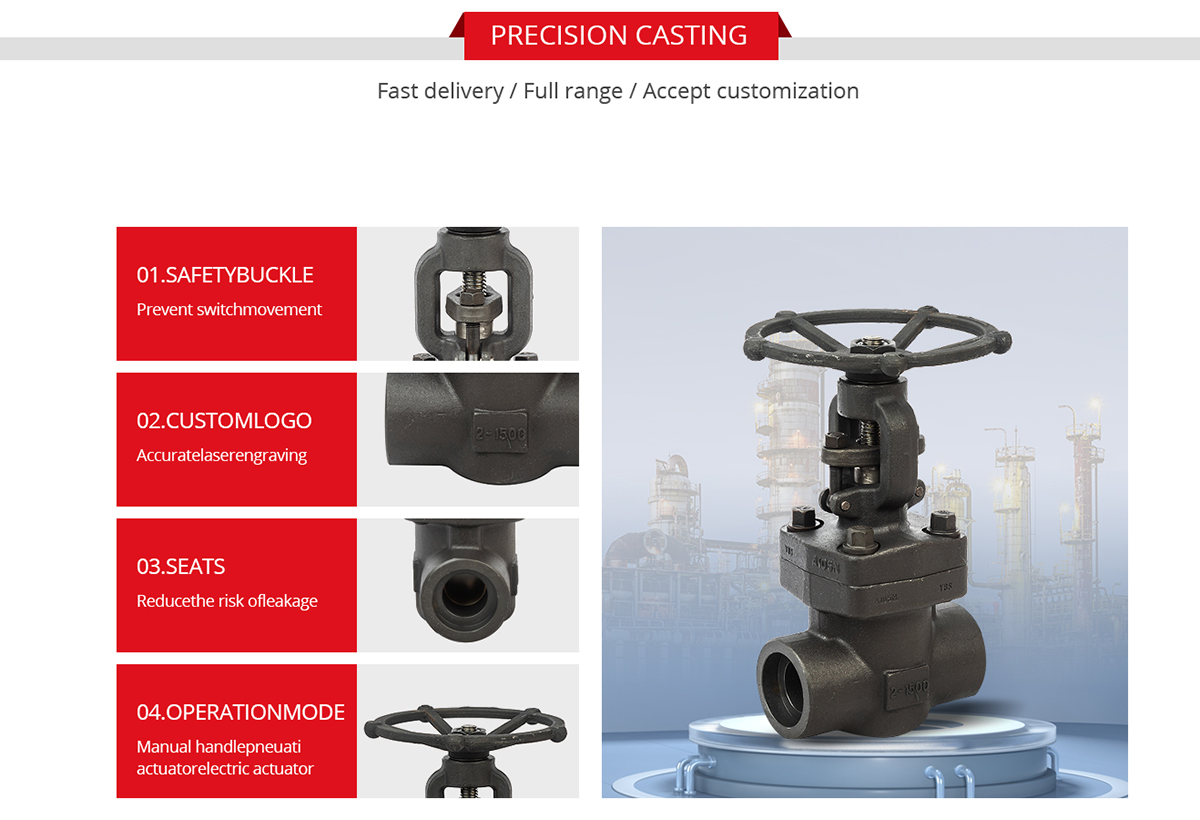

Integral flange self-sealing globe valve is designed and manufactured in strict accordance with API602, BS 5352 standards. The valve disc is positioned along the center for lifting movement (the bushing is made of a special material with good wear resistance and a small friction coefficient), flexible and reliable, excellent sealing performance. Integral flange self-sealing globe valves are widely used in pipelines in the petroleum, chemical, pharmaceutical, and electric power industries.

Product Description

Integral flange self-sealing globe valve is designed and manufactured in strict accordance with API602, BS 5352 standards. The valve disc is positioned along the center for lifting movement (the bushing is made of a special material with good wear resistance and a small friction coefficient), flexible and reliable, excellent sealing performance. Integral flange self-sealing globe valves are widely used in pipelines in the petroleum, chemical, pharmaceutical, and electric power industries.

Product Structure Characteristics

1.Zero emission, fireproof structure

2.Helium leak test

3.3000 cycles according to working conditions

4.Low-emission secondary seal

5.Graphite packing seal

6.The back seat is in the open position

7.Full thickness connection welding

8.Welded or bolted bonnet type

9.The valve seat and the wedge surface are the stellite faces

Advantages

1. The hand wheel is forged from wrought iron and has the shape of a handle, which increases friction appropriately and is easy to open. And show obvious "open" and "close" marks. Optional impact handwheel with large diameter and higher pressure.

2. The stem nut is made of high nickel ductile iron with a "T" thread, and the stem has torque transmission. The bonnet gland packing and pressure split design ensure the concentricity of the valve stem. A reasonable stuffing box ensures that the Integral flange self-sealing globe valve does not leak. Meet the requirements of environmental protection.

3. Valve cover with sealing seat. Meet the API requirements of the American Petroleum Institute and the British BS standard.