When using imported high-pressure and low-temperature shut-off valves, it is necessary to choose the appropriate brand, model, and specification according to the actual application needs. At the same time, it is important to refer to the manufacturer's recommendations and instructions to ensure the safe, reliable, and effective operation of the valve. During installation and use, it is necessary to follow the correct installation and maintenance methods, regularly inspect and maintain valves, and ensure that they are in good working condition. It should be noted that there may be some special problems encountered during use, such as material embrittlement at low temperatures and decreased sealing performance. Therefore, special attention should be paid to the maintenance and upkeep of the valve during use, promptly identifying and resolving issues to ensure the safe, reliable, and effective operation of the valve.

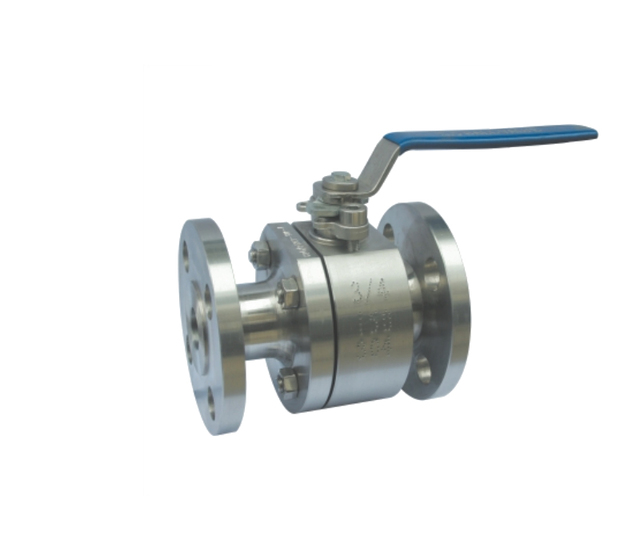

View Products