What is an ultra-low temperature bellows globe valve? Ultra low temperature bellows globe valve is a type of valve suitable for medium temperatures below -150 ℃. It belongs to the category of ultra-low temperature valves and has a specific structure and material to adapt to the working conditions of ultra-low temperature environments. This type of valve usually adopts a bellows structure because special structural design is required for the sealing of the valve stem and body under ultra-low temperature conditions. Although there are some limitations to the use of corrugated pipes, their application in ultra-low temperature valves is common, especially in structures that require packing box sealing. The design of ultra-low temperature bellows globe valve takes into account the sealing performance and operational reliability at extremely low temperatures. Its packing box sealing structure is simple to process and easy to maintain. However, in order to ensure the sealing effect in environments below -40 ℃, it is necessary to choose packing with low temperature characteristics and keep the packing box as far away from the material as possible. In addition, the materials of ultra-low temperature bellows globe valves usually include carbon steel, stainless steel, alloy steel, duplex steel, etc. These materials have good low-temperature performance and corrosion resistance, and can adapt to extreme working environments in industries such as petroleum, chemical, natural gas, petrochemical, and coal chemical. There are various driving methods for valves, including manual, gear transmission, electric, pneumatic, etc., to meet the needs of different application scenarios

What is an ultra-low temperature bellows globe valve?

What is an ultra-low temperature bellows globe valve?

Ultra low temperature bellows globe valve is a type of valve suitable for medium temperatures below -150 ℃. It belongs to the category of ultra-low temperature valves and has a specific structure and material to adapt to the working conditions of ultra-low temperature environments. This type of valve usually adopts a bellows structure because special structural design is required for the sealing of the valve stem and body under ultra-low temperature conditions. Although there are some limitations to the use of corrugated pipes, their application in ultra-low temperature valves is common, especially in structures that require packing box sealing. The design of ultra-low temperature bellows globe valve takes into account the sealing performance and operational reliability at extremely low temperatures. Its packing box sealing structure is simple to process and easy to maintain. However, in order to ensure the sealing effect in environments below -40 ℃, it is necessary to choose packing with low temperature characteristics and keep the packing box as far away from the material as possible.

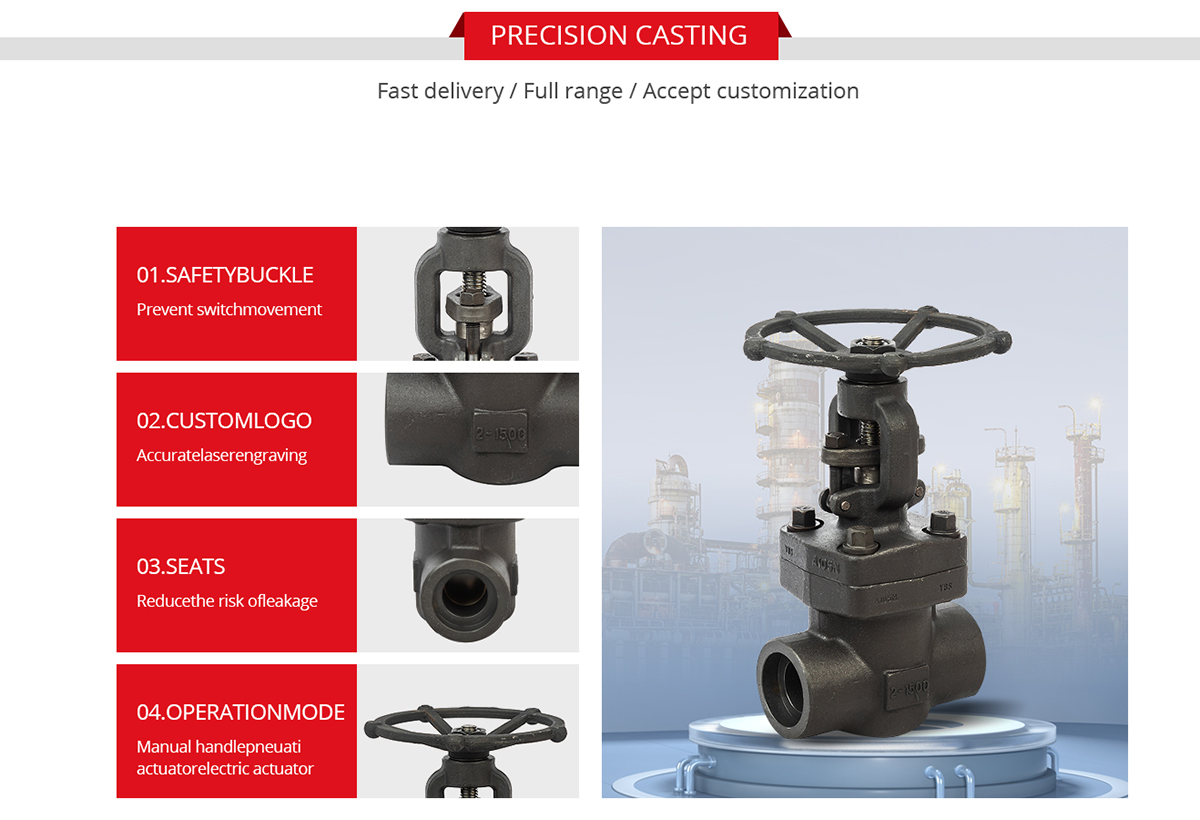

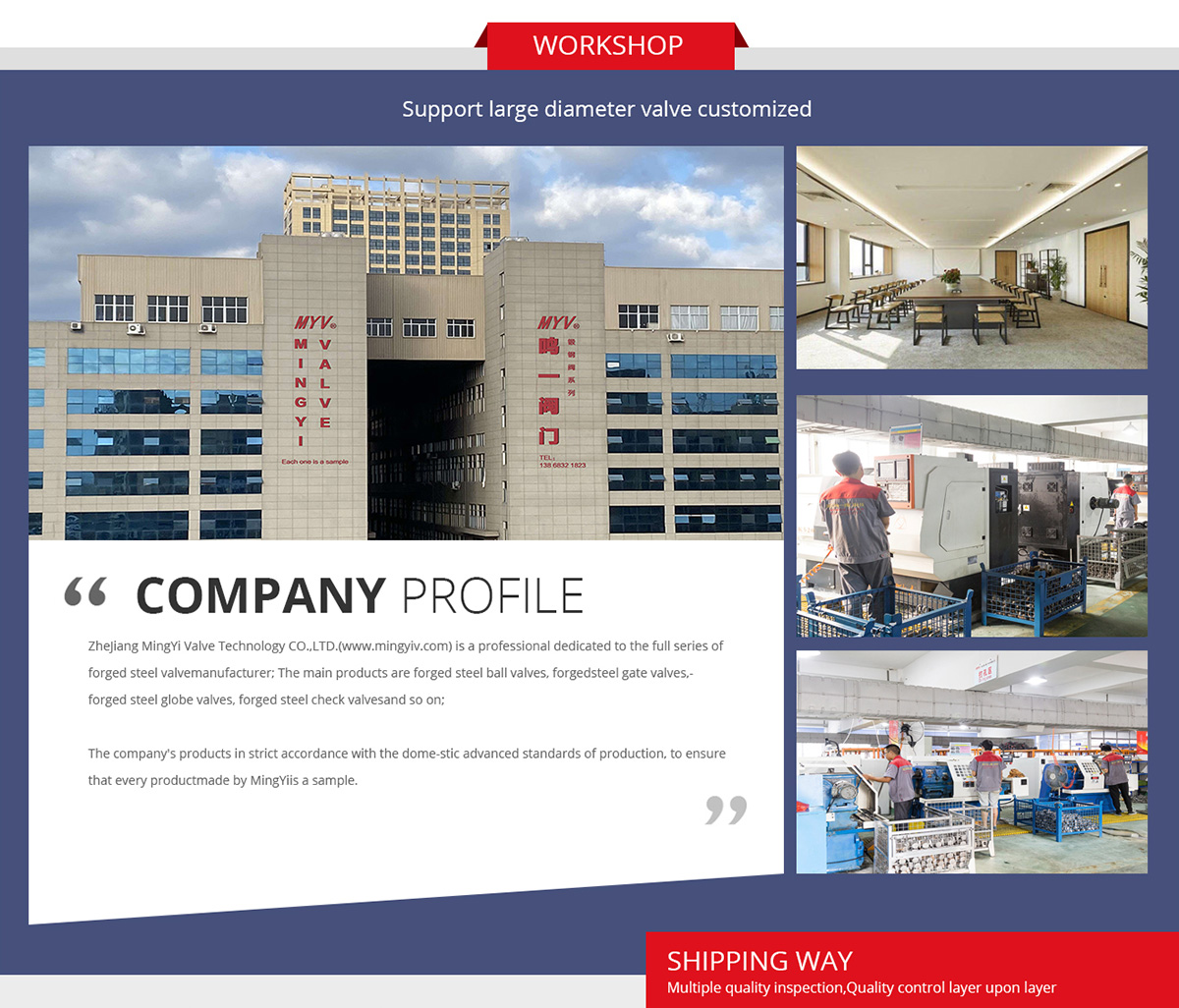

In addition, the materials of ultra-low temperature bellows globe valves usually include carbon steel, stainless steel, alloy steel, duplex steel, etc. These materials have good low-temperature performance and corrosion resistance, and can adapt to extreme working environments in industries such as petroleum, chemical, natural gas, petrochemical, and coal chemical. There are various driving methods for valves, including manual, gear transmission, electric, pneumatic, etc., to meet the needs of different application scenarios