Choosing valves for cryogenic service can be complicated. The production, transport and storage of liquefied gases such as oxygen, nitrogen and natural gas demand a thoughtful solution.Low temperature self-sealing integral gate valves are produced to the rigid ‘Controlled Quality’ standards that assure dependable operating performance at sub-zero temperatures. The production, transport and storage of liquefied gases such as oxygen, nitrogen, natural gas (down to –425°F) demand a thoughtful solution.

Product Description

Choosing valves for cryogenic service can be complicated. The production, transport and storage of liquefied gases such as oxygen, nitrogen and natural gas demand a thoughtful solution.Low temperature self-sealing integral gate valves are produced to the rigid ‘Controlled Quality’ standards that assure dependable operating performance at sub-zero temperatures. The production, transport and storage of liquefied gases such as oxygen, nitrogen, natural gas (down to –425°F) demand a thoughtful solution.

Product Structure Characteristics

Our custom integral designed bonnets and modified extended bonnets provide safe, dependable service to LNG receiving terminals and liquification facilities as well as processes using liquid nitrogen and hydrogen. The main structural feature of Low temperature self-sealing integral gate valves is the enclosed vapor chamber which isolates the packing from the cryogenic fluid allowing the packing to function properly. Valves for cryogenic service can be assembled in a clean room and be lubricant free or utilize lubricants compatible for cold service. The valves should be free from machine oil, grease, dirt or any foreign material. Any of these can inhibit the Low temperature self-sealing integral gate valve’s performance.

Advantages

1. Light weight: The body is made of high-grade nodular black cast iron, which is about 20% to 30% lighter than the traditional gate valve, and is easy to install and maintain.

2. Flat-bottomed gate seat: The bottom of the elastic seat-sealed gate valve adopts the same flat-bottom design as the water pipe machine, which is not easy to cause debris accumulation and makes the fluid flow unimpeded.

3. Overall rubber encapsulation: Low temperature self-sealing integral gate valve adopts high-quality rubber for the overall inner and outer rubber. The rubber and the ductile cast gate are firmly connected, not easy to fall off and have good elastic memory.

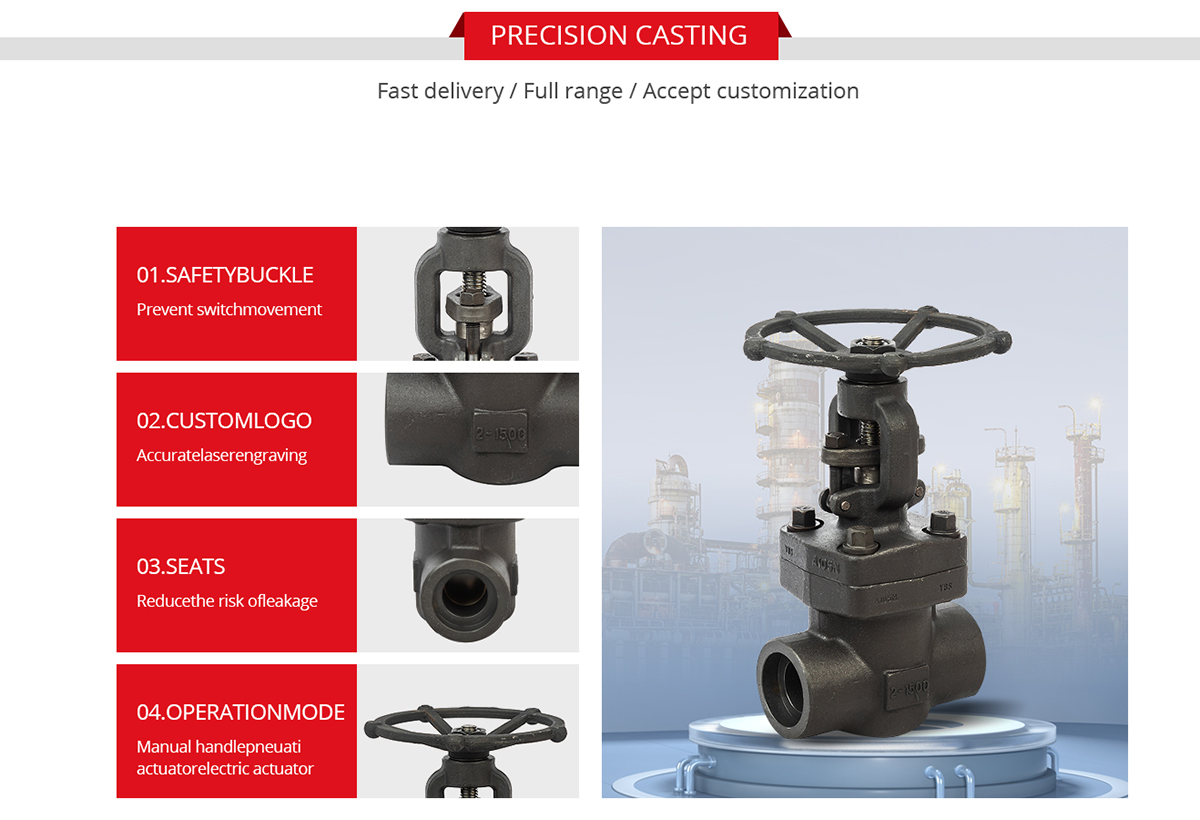

4. Precision casting valve body: The valve body adopts precision casting, and the accurate geometric dimensions make the inside of the valve body without any fine processing to ensure the sealing of the valve.