What is a stainless steel hard seal ball valve? Stainless steel hard sealed ball valve is an industrial equipment characterized by a metal to metal pairing of the sealing pair (i.e. the valve seat sealing surface and the ball sealing surface) of the ball valve. The structural form of this ball valve is divided into floating ball type and fixed ball type, and the connection forms include flange connection, welding connection, and threaded connection. The sealing characteristics of hard sealed ball valves are mainly the use of metal sealing pairs, which have the advantages of a wide temperature range, similar thermal expansion coefficients of various metals, and can achieve basic consistency as long as selected properly, which is conducive to coordinating temperature difference deformation. However, its disadvantage is that the material hardness is high, and the required specific pressure to achieve sealing is high. Even if pre tightening force is used to achieve sealing, the wear between the valve seat and the ball is also significant due to the high specific pressure of the seal. Moreover, due to the high friction coefficient of the metal sealing surface, the opening and closing torque of the ball valve is relatively large. Therefore, most hard sealed ball valves use elastic sealing pairs, which have reliable performance, strong elastic compensation ability, wide temperature range, and are suitable for both floating ball valves and fixed ball valves. The wide application of stainless steel hard sealed ball valves benefits from their unique advantages: compact structure, easy operation and maintenance, reliable sealing, small volume, can be made into large diameters, simple structure, and not easily eroded by media. These characteristics make stainless steel hard sealed ball valves perform well in controlling the flow of various types of fluids such as air, water, steam, various corrosive media, mud, oil, liquid metal, and radioactive media, and therefore have been widely used in various industries。

What is a stainless steel hard seal ball valve?

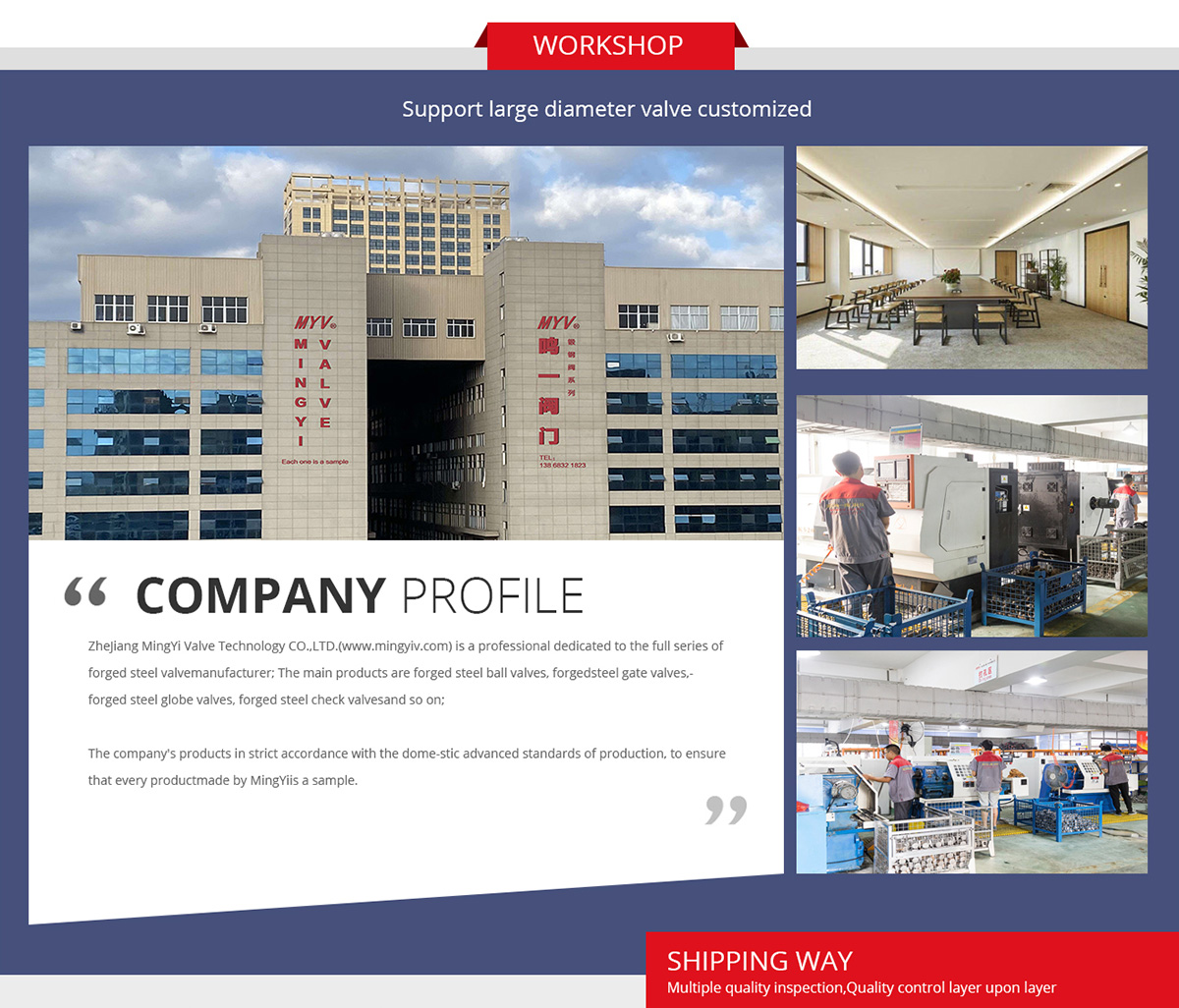

Stainless steel hard sealed ball valve is an industrial equipment characterized by a metal to metal pairing of the sealing pair (i.e. the valve seat sealing surface and the ball sealing surface) of the ball valve. The structural form of this ball valve is divided into floating ball type and fixed ball type, and the connection forms include flange connection, welding connection, and threaded connection. The sealing characteristics of hard sealed ball valves are mainly the use of metal sealing pairs, which have the advantages of a wide temperature range, similar thermal expansion coefficients of various metals, and can achieve basic consistency as long as selected properly, which is conducive to coordinating temperature difference deformation. However, its disadvantage is that the material hardness is high, and the required specific pressure to achieve sealing is high. Even if pre tightening force is used to achieve sealing, the wear between the valve seat and the ball is also significant due to the high specific pressure of the seal. Moreover, due to the high friction coefficient of the metal sealing surface, the opening and closing torque of the ball valve is relatively large. Therefore, most hard sealed ball valves use elastic sealing pairs, which have reliable performance, strong elastic compensation ability, wide temperature range, and are suitable for both floating ball valves and fixed ball valves.

The wide application of stainless steel hard sealed ball valves benefits from their unique advantages: compact structure, easy operation and maintenance, reliable sealing, small volume, can be made into large diameters, simple structure, and not easily eroded by media. These characteristics make stainless steel hard sealed ball valves perform well in controlling the flow of various types of fluids such as air, water, steam, various corrosive media, mud, oil, liquid metal, and radioactive media, and therefore have been widely used in various industries。

Product Description:

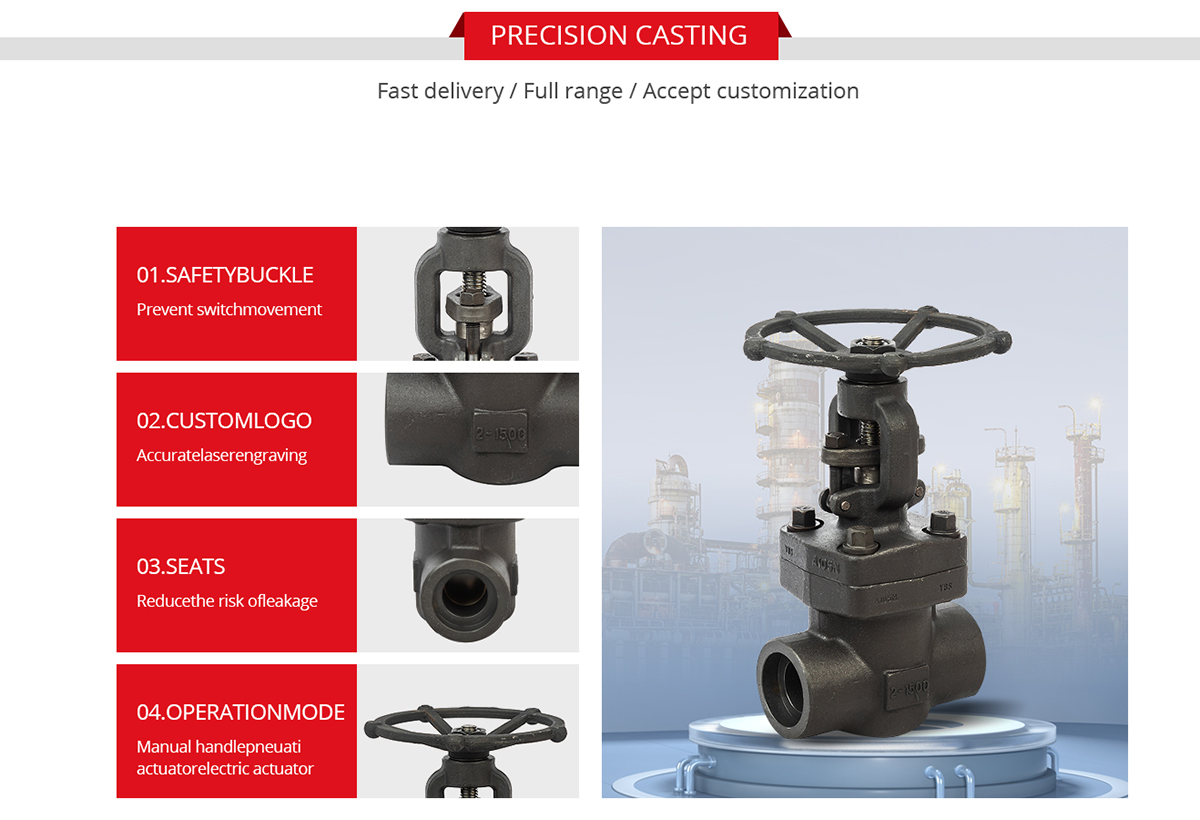

main features

Full diameter/reduced diameter

90 degree positioning and lockable structure

Special form of "Y" head handle

A pair of butterfly shaped spring pads facing each other

Anti blowing valve stem

Double sealing structure in the middle of the valve stem

Bolt and threaded gasket seal valve cover

Product specifications

Design Specification: API 6D

Structural length: ANSI B16.10

Connection standards: ANSI/ASME B1.20.1, ASME B16.11

Pressure test: API598/API6D

Product Range

Main material: forged steel

Nominal diameter: 3/8 "-2"

Pressure range: 150LB-2500LB

Applicable temperature: ≤ 120 ℃

Operation mode: manual, etc

Applicable media: water, steam, oil, etc.

Stainless steel ball valves can be tightly closed with only a 90 degree rotation and a small rotational torque. The completely equal valve body cavity provides a low resistance, straight through flow channel for the medium. The main characteristics of a ball valve are its compact structure, easy operation and maintenance. Stainless steel ball valves can be used to control the flow of various types of fluids such as air, water, steam, various corrosive media, mud, oil, liquid metal, and radioactive media. The valve body of a ball valve can be integral or modular. This type of valve should generally be installed horizontally in pipelines. Classification of stainless steel ball valves: stainless steel pneumatic ball valves, stainless steel electric ball valves, stainless steel manual ball valves. The material of stainless steel ball valves is divided into 304, 316, 321 stainless steel ball valves.