What is a duplex stainless steel gate valve The duplex stainless steel gate valve is a device for separating and merging or switching flow direction, made of duplex stainless steel. This type of valve is mainly used for fluid transportation, cutting off, and circulation, with functions such as shut-off, diversion, pressure stabilization, and diversion. The gate of the duplex stainless steel gate valve moves linearly with the valve stem, and its opening and closing component is the gate. The direction of the gate's movement is perpendicular to the direction of the fluid. This design allows the gate valve to only perform fully open and fully closed operations, and cannot be adjusted or throttled. The gate of a duplex stainless steel gate valve has two sealing surfaces, and the most commonly used mode is that the two sealing surfaces of the gate valve form a wedge shape. The wedge angle varies with the valve parameters, usually 50 °, and 2 ° 52 'when the medium temperature is not high. The gate of a wedge gate valve can be made as a whole, called a rigid gate; It can also be made into a gate that can produce slight deformation to improve its processability and compensate for the deviation of the sealing surface angle during the processing. This type of gate is called an elastic gate。

What is a duplex stainless steel gate valve?

The duplex stainless steel gate valve is a device for separating and merging or switching flow direction, made of duplex stainless steel. This type of valve is mainly used for fluid transportation, cutting off, and circulation, with functions such as shut-off, diversion, pressure stabilization, and diversion. The gate of the duplex stainless steel gate valve moves linearly with the valve stem, and its opening and closing component is the gate. The direction of the gate's movement is perpendicular to the direction of the fluid. This design allows the gate valve to only perform fully open and fully closed operations, and cannot be adjusted or throttled. The gate of a duplex stainless steel gate valve has two sealing surfaces, and the most commonly used mode is that the two sealing surfaces of the gate valve form a wedge shape. The wedge angle varies with the valve parameters, usually 50 °, and 2 ° 52 'when the medium temperature is not high. The gate of a wedge gate valve can be made as a whole, called a rigid gate; It can also be made into a gate that can produce slight deformation to improve its processability and compensate for the deviation of the sealing surface angle during the processing. This type of gate is called an elastic gate

Forged steel gate valves are suitable for small-diameter pipelines with Class 150-2500 and working temperatures of -29~425 ℃ (carbon steel) or -29~500 ℃ (stainless steel). They are used to cut off or connect media in pipelines. Different materials are selected and can be applied to various media such as water, steam, oil, nitric acid, acetic acid, oxidizing media, urea, etc.

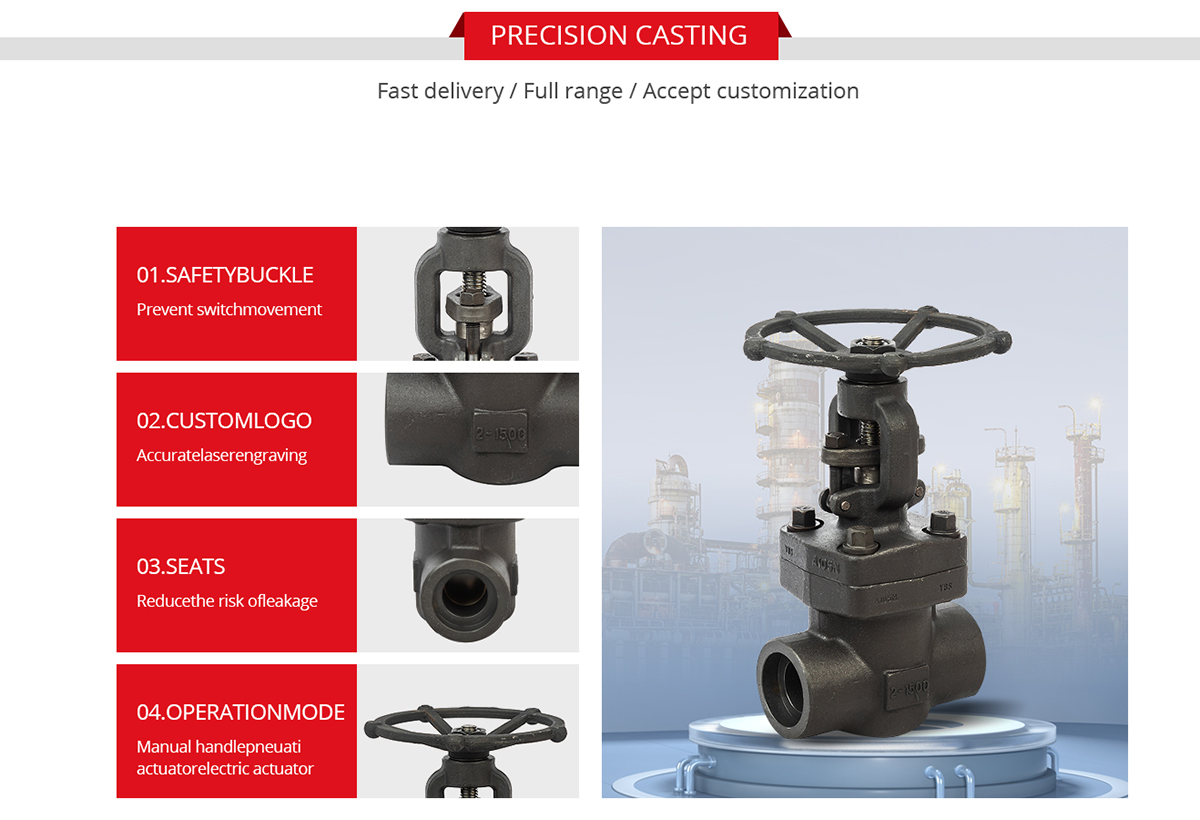

Product Description:

Main features:

Full diameter or reduced diameter

2. Self sealing valve cover

3. Bright pole with bracket

4. Automatic adjustable packing sleeve at both ends;

5. Reverse sealing of the body

6. Integral valve body flange

7. Ring connection valve body valve cover gasket

8. Bolt type valve covers, threaded seals, welded valve covers, or self sealing valve covers with wrapped gaskets

Product specifications:

Design standards: API 602, ANSI B16.34

Structural length: ANSI/ASME B16.10

Connection standard: ANSI/ASME B16.5

Experimental verification: APl598

Main material: forged steel

Nominal diameter: 3/8 "-4"

Pressure range: 150LB-4500LB

Applicable temperature: -29-425 ℃

Applicable media: water, oil, natural gas, etc