Forged steel self sealing globe valve refers to a valve in which the closing element (valve disc) moves along the centerline of the valve seat. According to the movement of the valve disc, the change in the valve seat opening is directly proportional to the stroke of the valve disc. Due to the relatively short opening or closing stroke of the valve stem and the highly reliable shut-off function of this type of valve.

The integral flange self sealing globe valve is a type of valve characterized by the closure element (valve disc) moving along the centerline of the valve seat, thereby achieving the cutoff, connection, or regulation of the medium in the pipeline. The design of this valve requires pressure to be applied to the valve disc when closed to force the sealing surface to not leak, maintaining good sealing performance even in high-pressure environments. Integral flange self sealing globe valves typically have the following characteristics:

Structural features: The integral flange self sealing globe valve has three valve cover designs, including bolt type valve cover, welded valve cover, and self sealing valve cover. The bolt type valve cover is connected by concave and convex surfaces, using stainless steel strips and flexible graphite wrapped gaskets; Welded valve covers are welded after being sealed with threads or directly welded with rigidity; The self sealing valve cover is connected to the self sealing valve cover through threads to achieve self sealing function.

Material and application: This type of valve is usually made of forged steel, with materials including F304, F316, F316L, etc., suitable for various media such as water, steam, oil, etc. Its working temperature and pressure environment are widely adaptable, with corresponding models available from atmospheric pressure to high pressure.

Sealing performance: The design of the integral flange self sealing globe valve focuses on sealing performance, especially in high-pressure environments, where its sealing performance is more outstanding. The middle chamber adopts a self sealing structure, and the higher the pressure, the better the sealing performance, ensuring reliability and safety under various working conditions.

Service life: Due to the use of materials that are resistant to cavitation, corrosion, and erosion, as well as hard alloy sealing surfaces, this valve has a long service life and can operate stably for a long time in harsh working environments.

The integral flange self sealing globe valve is widely used in the fields of petroleum, chemical, natural gas, water supply, etc., and is one of the indispensable and important equipment in industrial pipeline systems

Product advantages:

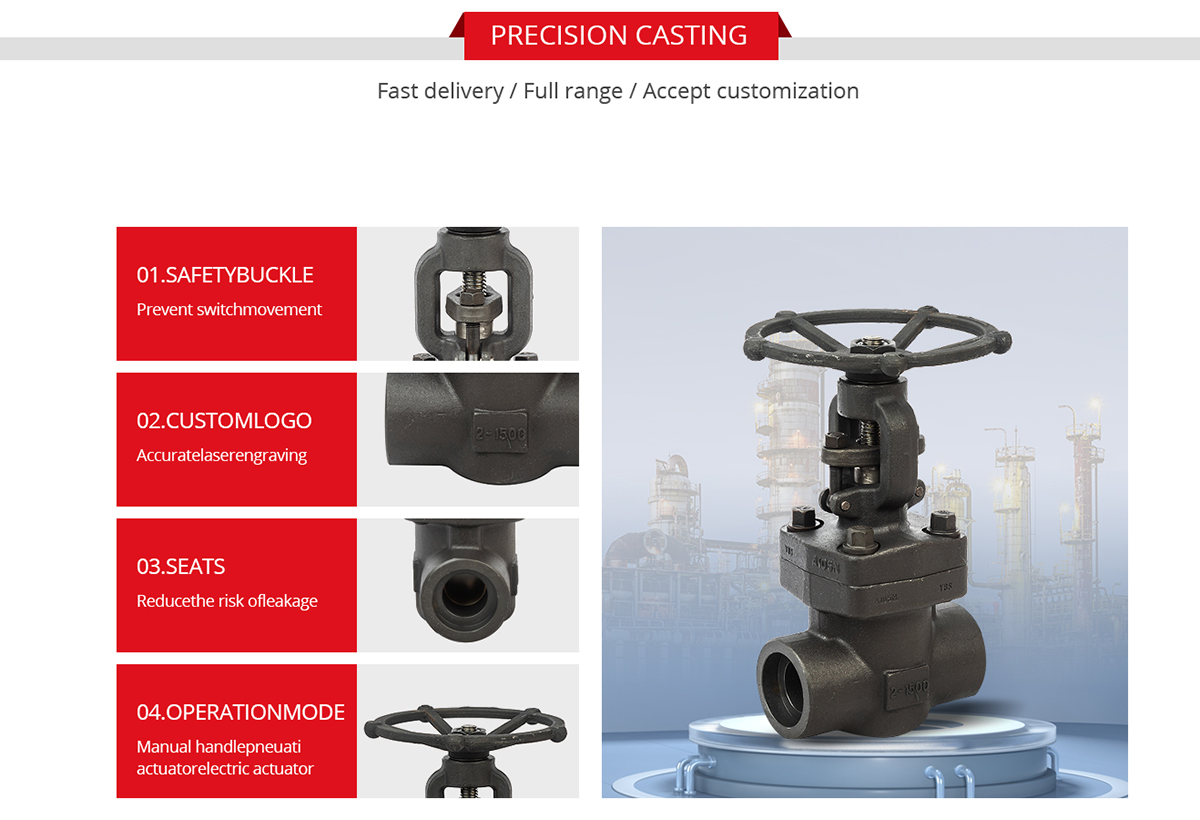

1. The structure is simple and easy to manufacture and maintain.

2. Small work schedule and short opening and closing time.

3. Good sealing performance, low friction between sealing surfaces, and long service life.

Technical indicators:

Caliber: 2 "to 8"

Pound scale: 900~2500;

Bright stem, lifting valve stem

Pressure self sealing

Cone valve disc

Reverse sealing welding

Equipped with bypass device (optional)

Equipped with locking device (optional)

Gearbox transmission (optional)

matters needing attention:

1. The shut-off valve operated by handwheel and handle can be installed at any position in the pipeline.

2. Handwheels, handles, and dynamic mechanisms are not allowed for lifting purposes.

3. The flow direction of the medium should be consistent with the arrow direction shown on the valve body.

Product advantages:

1. The structure is simple and easy to manufacture and maintain.

2. Small work schedule and short opening and closing time.

3. Good sealing performance, low friction between sealing surfaces, and long service life.

Technical indicators:

Caliber: 2 "to 8"

Pound scale: 900~2500;

Bright stem, lifting valve stem

Pressure self sealing

Cone valve disc

Reverse sealing welding

Equipped with bypass device (optional)

Equipped with locking device (optional)

Gearbox transmission (optional)

matters needing attention:

1. The shut-off valve operated by handwheel and handle can be installed at any position in the pipeline.

2. Handwheels, handles, and dynamic mechanisms are not allowed for lifting purposes.

3. The flow direction of the medium should be consistent with the arrow direction shown on the valve body.