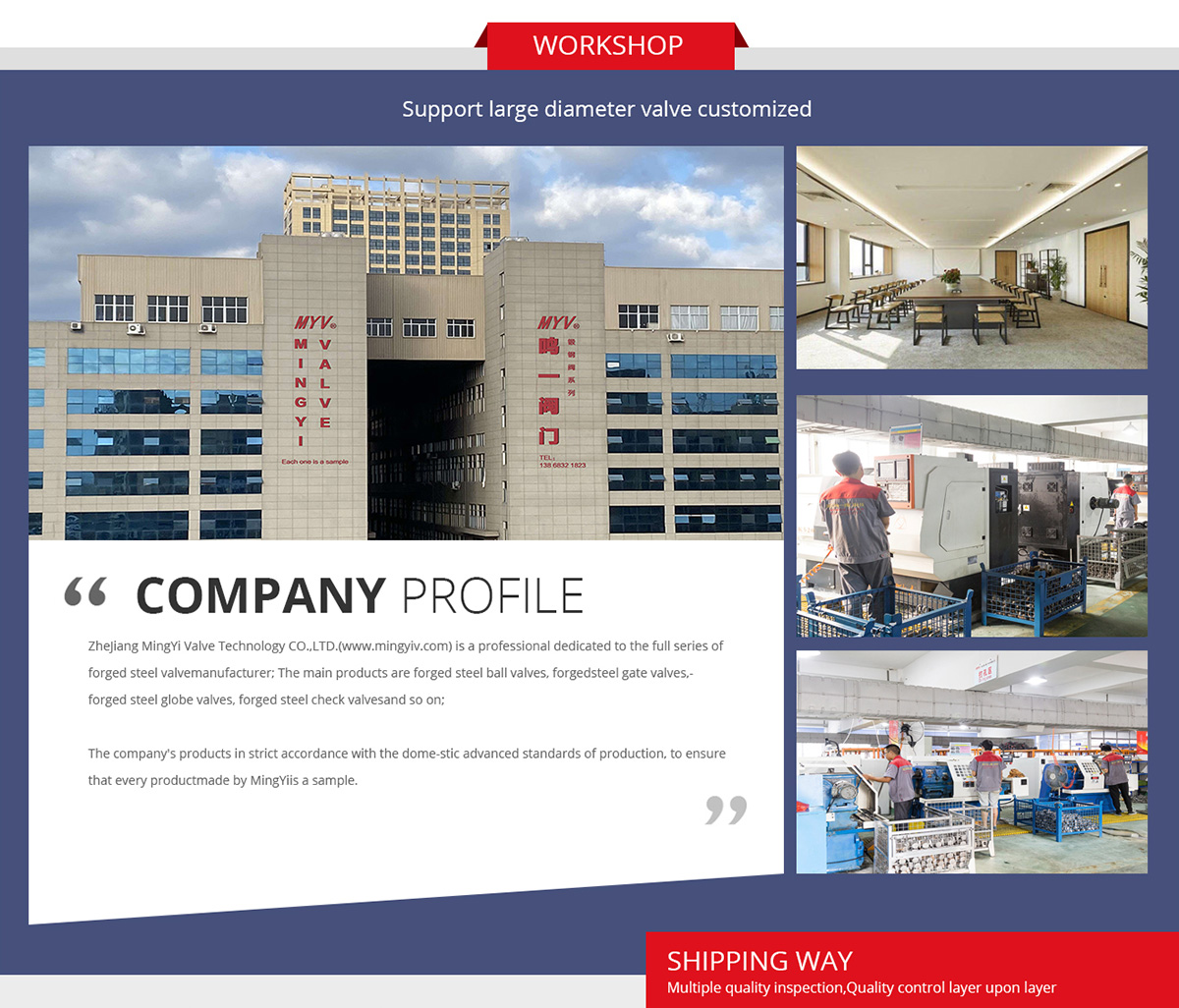

We have passed ISO9001, 14001, 18001 and other certifications, the company's products in strict accordance with the advanced domestic standards of production, to ensure that every product made by Mingyi valve is a sample.Since its establishment, the company has advocated the concept of quality, service, mutual win, and strictly build a sincere, humble, rigorous, professional service team.From the purchase of raw materials to the delivery of goods, all the processes are followed up by professional staff. Our ball valves are mainly three-way ball valves, DBB ball valves, threaded ball valves, welded ball valves, flange ball valves and so on.Mainly used in pipelines of oil and natural gas.Products can withstand high and low temperature, high pressure, corrosion resistance, and stable sealing performance, we can also according to your needs for production.All of our products are precisely adjusted and assembled by professionals, and are 100% tested by professionals and professional testing

Attributes:

| Brand | MYV | Applicable medium | Weak acid-base medium | Object of action | Fluid pipeline |

| Pressure environment | low pressure | Driving method | Manual | Flow direction | two-way |

| Accessories available | parts | Temperature environment | -196-200 | structural style | Floating ball valve |

| Valve standards | American Standard | Valve function | cut-off | Mode of action | Single action |

| Type (channel position) | Straight through type | Eccentricity requirements | Non eccentricity | Functional effects | Fast type |

|

Lining material |

sealing material | PCTFE | Sealing method | Soft sealing | |

| Applicable industries | chemical industry |

What is a ball valve?

There are two design forms for ball valves. One is a two piece structure, with threaded connections in the middle and sealed with PTFE gaskets; Another type is a three piece structure, with the middle part bolted together. Depending on the selected valve seat and gasket/packing material, it can adapt to different working temperatures and media

Product Description:

Product specifications

FAQ:

Q. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.

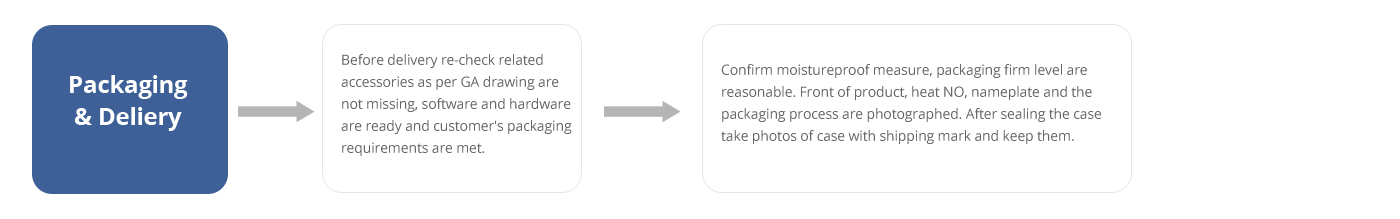

Q: What is your Packing details?

A:Plastic Bag, Carton & Plywood Case/According to customers' requirement.

Q: What is your terms of delivery?

A: FOB/CNF/CIF, Customers' Request, port includes NINGBO/SHANGHAI, Customers' Request.

Q: What's your delivery date?

A: It depends on the quantity of orders. Delivery date is 7-30 days. If you need emergency products, we can speed up the

production of the first arrangement.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine.

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 30-45 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ?

A: Yes, we could offer sample.

Q: What is your terms of payment ?

A: 30% T/T in advance, 70% balance before dispatch.

If you have another question, pls feel free to contact us.

Q: Can I request to change the form of packaging and transportation?

A: Yes, We can change the form of the packaging and transportation according to your request, but you have to bear their own costs incurred during this period and the spreads.

Q: Can I request to advance the shipment?

A: It should be depends on whether there is sufficient inventory in our warehouse.

Q: Can I have my own Logo on the product?

A: Yes, you can send us your drawing and we can make your logo, but you have to bear their own the cost.

Q: Can you produce the products according to my own drawings?

A: Yes, we can produce the products according to your drawings that will be most satisfy you.

Q: Can you do customized design and size?

A: Yes, ODM & OEM service are available. We could customize the size and design or even the bottle shape.

Q. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.

Q: What is your Packing details?

A:Plastic Bag, Carton & Plywood Case/According to customers' requirement.

Q: What is your terms of delivery?

A: FOB/CNF/CIF, Customers' Request, port includes NINGBO/SHANGHAI, Customers' Request.

Q: What's your delivery date?

A: It depends on the quantity of orders. Delivery date is 7-30 days. If you need emergency products, we can speed up the

production of the first arrangement.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine.

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 30-45 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ?

A: Yes, we could offer sample.

Q: What is your terms of payment ?

A: 30% T/T in advance, 70% balance before dispatch.

If you have another question, pls feel free to contact us.

Q: Can I request to change the form of packaging and transportation?

A: Yes, We can change the form of the packaging and transportation according to your request, but you have to bear their own costs incurred during this period and the spreads.

Q: Can I request to advance the shipment?

A: It should be depends on whether there is sufficient inventory in our warehouse.

Q: Can I have my own Logo on the product?

A: Yes, you can send us your drawing and we can make your logo, but you have to bear their own the cost.

Q: Can you produce the products according to my own drawings?

A: Yes, we can produce the products according to your drawings that will be most satisfy you.

Q: Can you do customized design and size?

A: Yes, ODM & OEM service are available. We could customize the size and design or even the bottle shape.

Strive for excellence in every aspect

1. Quality: Carefully produce each product, ensuring quality

2. Price: Factory direct sales, no intermediate links, much cheaper than offline specialty stores

3. Workmanship: With superb technology, every detail is controlled in place and strives for excellence

4. Material: Choose high-quality materials, rich production experience, and better understand your needs